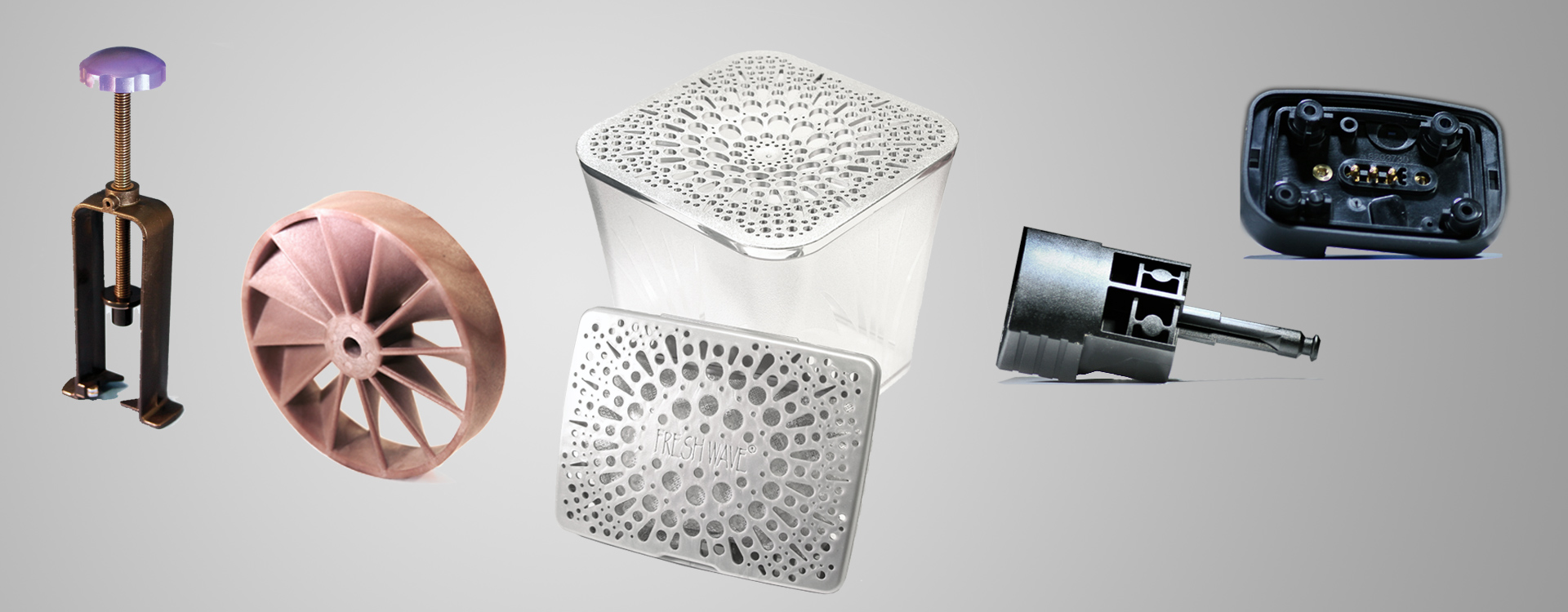

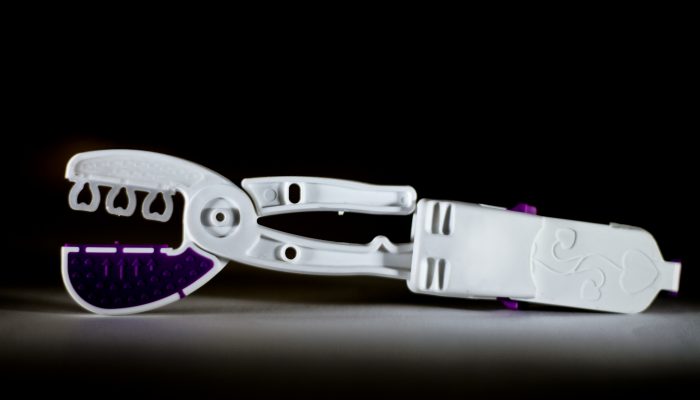

From short, prototype runs to million-piece production runs, Three R Plastics will exceed your expectations. Three R Plastics uses molding presses with state of the art technology to ensure quality that is consistent from part to part and run to run.

- Short Run Prototype Molding

- Million+ Production Runs

- 40 Ton – 400 Ton Capacity

- Robotics

- Overmolding

- Quick Change Tooling